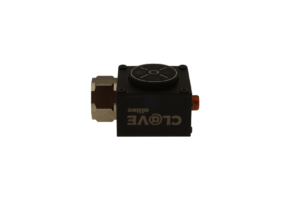

The CL@VE system is a revolutionary device designed to assess the overall technical condition of machine components, and prevent unexpected failures. This compact sensor integrates various measurement capabilities, such as 3D vibrations, sound, ultrasound, alternating magnetic fields, rotational speed, and temperature. With its wide array of built-in functions and interfaces, the CL@VE system offers many applications and versatility.

Easy Adaptability:

The CL@VE system can be connected to a smartphone or the VIDIA diagnostic cloud, allowing it to adapt to the user’s level of expertise. Initially, the device functions as a simple vibration sensor, providing basic technical condition monitoring capabilities. However, as the user gains experience, they can harness the full potential of the CL@VE system for multi-domain fault diagnosis and failure prediction of machine components.

Streamlined Data Collection and Analysis:

The CL@VE system includes powerful software that optimizes data collection and analysis, which speeds up machine diagnostics. However, when time constraints limit the user’s ability to investigate and analyze machine conditions, installing multiple CL@VE sensors at critical points on the machine enables real-time technical condition monitoring and transmission of component condition information to the automation system. An expert can handle the data analysis remotely by retrieving the measurement results from the sensor’s memory. The CL@VE system can also send signals directly to the cloud, notifying the user when the machine condition deteriorates.

Application across Different Industries:

The CL@VE system finds applications in various industrial plants, delivering significant improvements in the efficiency and effectiveness of maintenance teams. Users have reported increased machine availability and reduced production losses. For diagnosticians and service technicians, the CL@VE system offers the opportunity to provide a reliable and efficient solution to the plants they work with, eliminating unnecessary travel. By utilizing the VIDIA.cloud or VIDIA.server environment, the efficiency of their work can be further enhanced.

Technical Parameters and Capabilities:

Despite its compact size, the CL@VE system boasts impressive technical parameters and capabilities, making it a standout device in the machine diagnostics market. Its features include a basic MEMS 3D accelerometer with a ±16g measurement range, high-frequency 1D MEMS accelerometer with a ±50g measurement range, MEMS microphone sensitive to audible sounds and ultrasonic waves, magnetic flux sensor with a ±3T measurement range, temperature sensor from -30°C to +110°C, digital input for rotation or phase sensor, 8GB memory for measurement and analysis results, Li-Ion battery with a 1200mAh capacity, Wi-Fi and Ethernet interfaces with Modbus/TCP, wireless interface for sensor cloud synchronization, 4-20 mA analog output, and two digital outputs.

Versatility in Applications:

The CL@VE system offers versatility in its applications and can serve as an IoT sensor, machine technical condition monitor, or signal recorder. Its mobile capabilities enable both offline workaround diagnostics and continuous supervision. With the ability to self-determine diagnostic parameters and communicate via wireless Wi-Fi and wired Ethernet/PoE interfaces, the CL@VE system can seamlessly integrate into existing infrastructure and contribute to the automation control system.

The CL@VE system is a game-changer in machine component evaluation. Its comprehensive range of measurement capabilities and user-friendly interfaces provide a powerful tool for fault diagnosis, failure prediction, and maintenance optimization. The CL@VE system’s versatility and adaptability make it a valuable asset across various industries, increasing machine availability and reducing production losses. Implementing the CL@VE system ensures proactive maintenance strategies and enhances overall operational efficiency.