The first version of the device won the title::

“Product of the year 2016 in Engineering and Maintenance for Industrial Establishments”

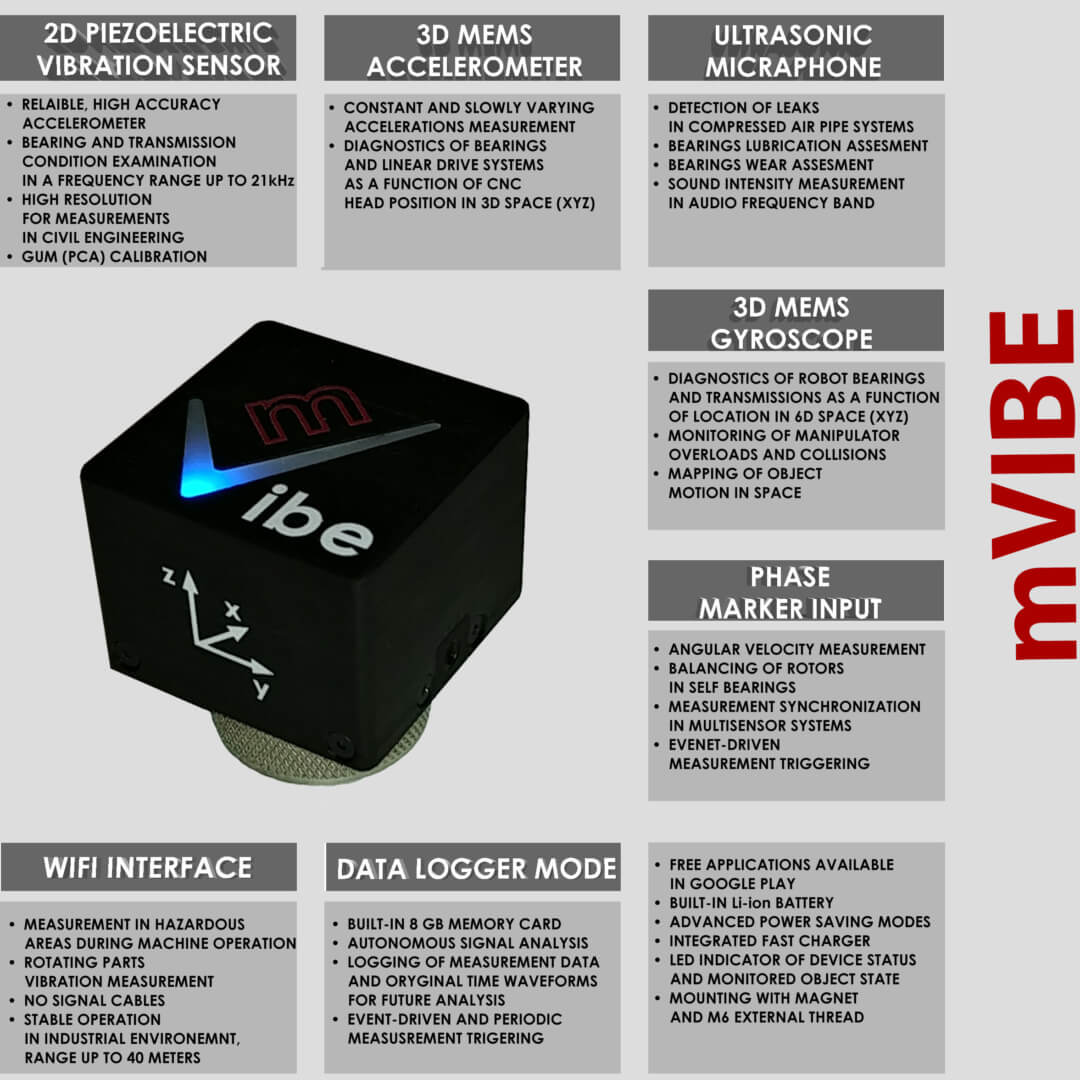

- WiFi interface

- High quality 2D piezoelectric vibration sensor

- 3D MEMS accelerometer

- Ultrasonic microphone

- 3D MEMS gyroscope

- Phase marker input

- Autonomous operation mode

- High capacity Li-ion battery

- 40 x 40 x 30 mm dimensions

- Mounting with M8x1 thread, magnet or by touch

- Free analytic software for Android based devices available

in Google Play:

Available software ![]()

Using mVIBE software you can conduct general assessment of machine technical condition according to obligatory standards. Moreover, you can identify basic faults by analysis of frequency spectrum and time waveform. Measurement results can be saved in a graphics file or exported to CSV file. The software is available free of charge in Google Play. You can get familiar with Its functionality using smartphone built-in sensors. Read more…

mVIDIA is an application, whose functionality will fulfill the needs of not only experienced experts but also it will help persons who just start their adventure with vibration measurement to learn predictive maintenance secrets.

Everyday tasks of maintenance service can be performed very effectively thanks to the set of analyses, which has been developed in cooperation with experts and intuitive graphical user interface. Read more…

Set ![]()

In basic version, mVIBE is offered as a set which includes a measurement cone and power supply with USB output and dedicated cable in addition to the sensor. Military class suitcase assures safe transport. A measurement cone useful for devices with aluminum cases and magnetic holder for curved surfaces are available as an option.

mVIBE

Vibration meter in a smartphone. (You can) Determine vibration level, analyse frequency spectrum and time waveform…

mVIBE is a multi-parameter wireless sensor for technical state evaluation of industrial equipment, including moving components of machines, its construction elements and construction objects. It is beyond a competition in the field of high performance, exceptional functionality, as well as the price.

Piezoelectric accelerometers are a main source of signal, which measure vibrations in two directions. Their outstanding parameters combined with 24-bit signal conversion allow to achieve accurate measurement results without necessity to change measurement ranges. Wide frequency band (0,5 Hz to 20 kHz) satisfies requirements of the most applications connected with technical condition assessment or damage diagnostics of machines and building constructions. Three-dimensional measurements within 0Hz to 1,5 kHz frequency range can be made with a built-in MEMS sensor. In combination with 3D highly sensitive silicon gyroscope it allows for determination of mVIBE movement in 6D space.

Measurement capabilities are complemented by an ultrasound microphone, which registers sound in range up to 51 kHz. It’s a tremendous tool to detect shocks, which occur in damaged bearings and gearboxes. Together with the dedicated software they allow to detect leakiness in compressed-air systems.

The measurement information from mVIBE sensor through WiFi interface is transmitted to a smartphone or a tablet. In permanent monitoring systems it can be sent directly to local or external diagnostic cloud. The mobile device with dedicated software installed acts as the user interface. Huge computing power and high-resolution screens combined with intuitive expertdriven software make signal analysis easy and effective.

In the basic system version mVIBE operates with mVIBE Soft tool available in GooglePlay. It creates fundamental tool for machines technical state evaluation and fault diagnosis. The advanced options covering signal storage in database, localization structure with NFC identification, fully configurable detailed signal analysis functions are offered by mVIDIA software. It can be integrated with cloud or server-based machine diagnostic environment VIDIA. Detailed information is available on manufacturer website www.alitec.pl or www.vibrations.pl.

mVIBE is powered by internal Li-Ion rechargeable battery. Its high capacity ensures operating time up to 8 hours (continuous measurement with data transmission). The sensor can be attached to the investigated object by magnetic holder or M6 screw thread. As an option magnetic holder for curved surfaces is delivered.

The highest accuracy of the mVIBE sensor can be confirmed by piezoelectric sensor calibration certificate issued by Polish Central Office of Measurement.

Software functionality covers

- Possibility for adjusting of a measured vibration parameter to the most of obligatory standards in machine and civil-engineering structures technical condition assessment

- Using of root-mean-square (RMS), peak (amplitude, 0-P) and peak-to-peak (P-P) values for vibration acceleration, velocity and displacement, in arbitrary frequency range in 1 Hz – 25,6 kHz band

- Possible definition of 3 alarm thresholds for vibration level

- Ultrasound leak detection in compressed air installations

- Sound signal for instantaneous exceeding of alarm threshold

- Vibration frequency spectrum plot, resolution of 1Hz

- 4 markers for frequency spectrum plot with markers of harmonic frequencies and sidebands

- Vibration time waveform plot

- 4 markers for a time waveform plot with automatic repeat

- Presentation of numerical values on a plot

- Saving of plot view settings in a graphics file

- Export of frequency spectrum and time waveform to a text file in CSV format

- On-line operation

- Readout of transducer precise sensitivity from measurement device

- Possibility for application testing with the use of smartphone built-in vibration sensors

- Automatic software update

You can conduct full fault diagnostic with the use of mVIDIA software. More information is available on the producer’s website.

| Type of sensors | 2 x piezoelectric accelerometers, ceramics PZT, shear mode, YZ direction 3 x MEMS accelerometer, XYZ direction 3 x MEMS gyroscope, XYZ direction 1 x microphone with ultrasonic capability |

| Range of measurements | ±50 g (other as an option) – PZT accelerometer ±16 g (other as an option) – MEMS accelerometer 120 dB SPL (20 Pa) – microphone |

| Frequency range of measured vibrations | PZT accelerometer: -3dB range 0,4 ... 21000 Hz; 10% range 0,8 ... 10500 Hz MEMS accelerometer: 0 ... 1500 Hz Microphone: 2% range 100 ... 10000 Hz; 8dB range 10 ... 20000 Hz and 40 ... 51200 Hz; 14dB range 20 ... 40000 kHz; |

| Type of analogue-digital converter | ΔΣ |

| Definition of analogue-digital converter | PZT accelerometer: 24 bits MEMS accelerometer: 16 bits MEMS gyroscope: 16 bits Microphone: 24 bits |

| Total noise level | PZT accelerometer: 0,8 mgRMS (results for range 50 g, fout = 65,536 kHz, frequency range 25,6 kHz) MEMS accelerometer: 3,0 mgRMS (results for range ±16 g, fout = 8,192 kHz, frequency range 1,5 kHz) Microphone: 30 dB SPL (0,6 mPa) (results for frequency range 20 Hz - 8 kHz) |

| Effective sampling frequency (fout) (frequency of updating output ) | PZT accelerometer, MEMS accelerometer, MEMS gyroscope: 65,536 kHz Microphone: 131,072 kHz |

| Chosen filters | low-pass analogue Butterworth filter, limit frequency f3dB high = 68 kHz (PZT accelerometer only) high-pass analogue first-order filter, limit frequency f3dB low = 0,5 Hz (PZT accelerometer only) high-pass digital anti-aliasing filter, linear phase, limit frequency set automatically to the value of f3dB high = 0,49 fout (f0,005dB high = 0,39 fout, f-100dB high = 0,54 fout) |

| Communication interfaces | IEEE802.11b/g/n WiFi, WPA2 frequency range 2,4 to 2,4835 GHz, maximally transmitted power 19.5 dBm@11b, 16.5 dBm@11g, 15.5 dBm@11n |

| Communication protocol | ATC MESbus |

| Operation conditions | temperature –5..+50°C; humidity: 10..90% RH |

| Level of protection | IP65, dust resistant case, resistant to water spout from any direction (for a covered microphone placed in a threaded connector) |

| Software | mVIBE, mVIDIA, VIDIA optional: API, control functions for Matlab, programming functions adjusted to the application |

| Power | Power a built-in battery Li-Ion 3,7V/1200mAh, integrated charger 5V/550mA work time between charging for a new device up to 8h (continuous data transmission) a built-in battery saving mechanisms and protection against overload or a full discharge |

| Installation | sensor external thread M6, included flat magnet holder and measurement pin |

| Geometric dimensions and mass | 40 x 40 x 32 mm (SxGxW), 95 g |

Reliability confirmed by Polish National Metrology Institute

Reliability confirmed by Polish National Metrology Institute